A significant portion of customer service inquiries are simple logistics questions. Customers want to know where their order is or if they can change the delivery address. By implementing an AI-powered system you can automate responses to these frequent queries. This provides customers with instant 24/7 access to tracking information and delivery options. This automation is a transformative element of modern e-commerce management. It allows human agents to focus on more complex and rewarding issues while elevating customer experience.

Table of Contents

ToggleThe true cost of "where is my order?"

The question “Where is my order?” seems simple. But it carries a heavy hidden cost for your business. Every time a customer contacts your support team for a tracking update it triggers a process. An agent must stop what they are doing, log into a shipping carrier’s website, locate the tracking number, and interpret the status. This might take five to ten minutes per request.

Now multiply that by dozens or hundreds of requests a day. You have a customer service team that is overwhelmed with repetitive tasks. This prevents them from solving more complex problems like returns or product issues. The high volume of inquiries can lead to long response times. This creates customer frustration even when the initial question was simple. You are paying a high price in labor and customer satisfaction just to share information that already exists.

The always-on logistics assistant

An AI-powered chatbot or support system acts as an always-on logistics assistant for your customers. It is integrated directly with your order management system and the shipping carriers you use. When a customer asks for a status update, the AI can instantly retrieve the latest tracking information.

It does not just parrot the tracking status from the carrier. It can interpret the data and provide a clear, helpful response. Instead of saying “In transit,” it can say, “Your package is currently in Chicago and is on track to be delivered to your doorstep by 3 PM this Friday.” This level of clarity reduces uncertainty and makes the customer feel informed.

This system is available every hour of every day. A customer wondering about their package at 10 PM on a Sunday gets an immediate answer. They don’t have to wait until Monday morning. This instant gratification meets the modern expectation for immediate information and drastically improves the customer’s perception of your service.

Handling complex requests automatically

The capabilities of these AI systems go far beyond simple tracking. They can be trained to handle a wide range of common logistics requests. This includes the ability to facilitate delivery changes.

A customer might message, “I won’t be home tomorrow, can I redirect my package to my office?” The AI can check the status of the shipment. If it is still at a certain hub, it can initiate the redirect process with the carrier automatically. It can then confirm the change with the customer and provide the new expected delivery date.

Similarly, the AI can start the return process. A customer can state they want to return an item. The AI can generate a return label, email it to the customer, and log the return in your system. It can answer common questions about return windows and policies. This turns a potentially lengthy support ticket into a self-service interaction that is resolved in seconds.

Empowering your human support team

The goal of this automation is not to replace human agents. It is to empower them. By automating the simple and repetitive questions, you free up your support team’s time and mental energy. They can then focus on issues that require empathy, critical thinking, and deep problem-solving.

These include complicated return situations, damaged items, or escalated customer concerns. These are the interactions that truly define your brand’s relationship with the customer. When your team is not burned out from answering a hundred tracking questions, they can provide the thoughtful and patient service that builds loyalty.

Your team transitions from a reactive force, constantly putting out small fires, to a proactive and strategic asset. They can focus on improving processes and creating a better overall customer journey. This shift in responsibility leads to higher job satisfaction and lower staff turnover.

Building a cohesive post-purchase experience

Seamless logistics support is the final piece of the post-purchase puzzle. It ensures that after a customer place an order, they feel supported and informed every step of the way. This automated communication works hand-in-hand with the physical delivery process to create a world-class experience.

Mastering this external-facing communication is a huge leap forward. But a truly resilient e-commerce operation also looks inward at its own processes. The next area of optimization lies in managing the inevitable flow of products back to your warehouse. Tackling the complexities of reversing logistics with intelligent systems is the key to transforming a cost center into a strategic advantage.

Key ai technologies powering modern logistics

Understanding the specific technologies behind AI agents helps logistics companies make informed decisions about implementation and investment.

A. Machine learning and predictive analytics

Machine learning forms the foundation of most AI applications in logistics. These algorithms learn from historical data to identify patterns that humans might miss. Supervised learning models predict delivery times based on thousands of past shipments, while unsupervised learning discovers hidden inefficiencies in warehouse layouts or transportation networks.

Predictive analytics takes this further by forecasting future outcomes. Companies use these tools to anticipate equipment failures, predict seasonal demand spikes, and estimate the likelihood of delivery delays. The more data these systems process, the more accurate their predictions become.

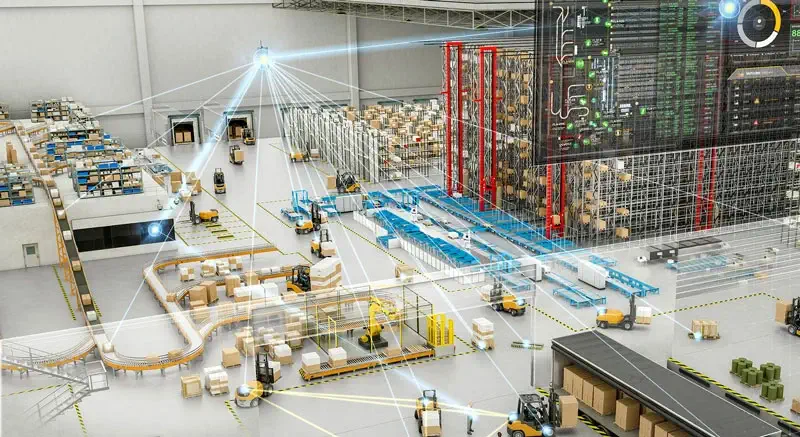

B. Computer vision for quality control and safety

Computer vision technology has transformed how logistics facilities monitor operations. Cameras equipped with AI can inspect packages for damage, verify that the correct items are being packed, and ensure products meet quality standards—all without human intervention.

Safety applications are equally important. Vision systems monitor warehouse floors to detect potential hazards, track whether workers are wearing proper safety equipment, and alert supervisors when unsafe conditions develop. Some systems can even recognize when a forklift is traveling too fast or when aisles become dangerously congested.

C. Natural language processing for customer service

NLP enables AI systems to understand and respond to customer inquiries in natural, conversational language. Chatbots and virtual assistants powered by NLP can answer questions about shipment status, handle routine requests, and even process returns or complaints.

These systems work 24/7 and can handle multiple conversations simultaneously in different languages. When issues become too complex, they seamlessly transfer customers to human agents along with a complete conversation history. This hybrid approach combines AI efficiency with human expertise where it matters most.

D. IoT integration and real-time data processing

The Internet of Things (IoT) creates networks of connected sensors throughout the supply chain. Smart sensors on trucks monitor temperature for refrigerated goods, GPS trackers provide location updates, and RFID tags enable automatic inventory counts as products move through facilities.

AI systems process this constant stream of IoT data in real time. They can detect when a refrigerated container’s temperature rises above safe levels, trigger alerts when shipments deviate from planned routes, or automatically update inventory records as products are loaded and unloaded.

Implementation strategies for ai in logistics

Successfully deploying AI agents requires careful planning and a structured approach. Here’s how logistics companies can maximize their chances of success.

A. Start with high-impact, low-complexity use cases

Companies often make the mistake of trying to transform everything at once. Instead, begin with specific problems where AI can deliver quick wins. Route optimization and demand forecasting are excellent starting points because they show measurable results relatively quickly and don’t require complete operational overhauls.

These early successes build confidence and provide valuable lessons about data quality, integration challenges, and change management. They also help justify further investment by demonstrating clear ROI to stakeholders.

B. Ensure data quality and infrastructure readiness

AI systems are only as good as the data they receive. Before implementing AI solutions, audit your existing data collection processes. Are sensors calibrated correctly? Is data stored in accessible formats? Are there gaps in historical records that could affect model training?

Infrastructure matters too. Cloud computing platforms provide the processing power AI needs, while robust network connections ensure real-time data flows smoothly. Many companies find that upgrading their IT infrastructure is necessary before AI implementation can succeed.

C. Build cross-functional teams and foster ai literacy

AI projects fail when they’re treated as purely IT initiatives. Successful implementation requires collaboration between operations staff, data scientists, IT professionals, and business leaders. Operations teams understand the real-world constraints and challenges, while data scientists know what AI can and cannot do.

Investing in AI literacy across the organization pays dividends. When warehouse managers understand basic AI concepts, they can identify new opportunities for automation. When drivers know how AI routing works, they trust the system’s recommendations more readily.

D. Choose between building, buying, or partnering

Companies face three main options: build custom AI solutions in-house, purchase commercial software, or partner with specialized providers. Each approach has trade-offs.

Building custom solutions offers maximum flexibility but requires significant technical expertise and development time. Commercial software gets you up and running faster but may not address your unique needs. Partnerships can provide the best of both worlds—specialized expertise combined with solutions tailored to your operations.

Overcoming common challenges in ai adoption

Even with careful planning, logistics companies encounter obstacles when implementing AI. Being prepared for these challenges increases the likelihood of success.

A. Data silos and integration complexities

Legacy systems often store data in incompatible formats across different departments. Transportation management systems don’t talk to warehouse management systems. Customer data lives separately from inventory data. Breaking down these silos is essential for AI to work effectively.

APIs and middleware solutions can bridge these gaps, but integration projects take time and resources. Many companies find that addressing data silos delivers benefits beyond AI—it improves overall operational visibility and decision-making.

B. Change management and employee concerns

Workers naturally worry that AI will eliminate their jobs. Address these concerns directly through transparent communication about AI’s role. Emphasize that AI handles repetitive tasks so humans can focus on complex problem-solving and customer relationships.

Involve employees in the implementation process. Their insights about current workflows are invaluable, and participation gives them ownership of the new systems. Training programs help staff develop skills to work alongside AI rather than compete with it.

C. Initial investment costs and Roi uncertainty

AI implementation requires upfront investment in technology, infrastructure, and training. Leadership may hesitate without guaranteed returns. Build a business case that includes both hard savings (reduced fuel costs, lower labor expenses) and soft benefits (improved customer satisfaction, better risk management).

Consider phased approaches that spread costs over time while delivering incremental value. Cloud-based solutions often have lower upfront costs than on-premises installations, making them more accessible for smaller operations.

D. Maintaining system performance and accuracy

AI models don’t remain accurate forever. As business conditions change, models trained on historical data may become less reliable. Establish processes for continuous monitoring and periodic retraining.

Create feedback loops where human experts review AI decisions and flag errors. This human-in-the-loop approach improves model accuracy while maintaining necessary oversight for critical decisions.

The future of ai in logistics

The logistics industry stands at the beginning of its AI transformation. Understanding emerging trends helps companies prepare for what’s coming next.

A. Autonomous vehicles and last-mile delivery

Self-driving trucks and delivery robots are moving from concept to reality. While fully autonomous long-haul trucking may still be years away, autonomous vehicles are already making last-mile deliveries in controlled environments like campuses and planned communities.

These technologies will reshape logistics networks. Companies are experimenting with hub-and-spoke models where autonomous vehicles handle predictable routes while human drivers focus on complex urban deliveries or customer interactions.

B. Blockchain integration for supply chain transparency

Combining AI with blockchain technology creates unprecedented supply chain visibility. Blockchain provides an immutable record of every transaction and handoff, while AI analyzes this data to detect anomalies, verify authenticity, and optimize flows.

This combination is particularly powerful for industries where provenance matters—pharmaceuticals, luxury goods, and food products. Customers can verify a product’s entire journey from manufacturer to their doorstep.

C. Hyper automation and end-to-end orchestration

The next generation of AI systems won’t just optimize individual processes—they’ll orchestrate entire supply chains. These systems will automatically adjust to disruptions, reroute shipments, notify customers, update inventory projections, and reorder stock without human intervention.

This hyper automation requires AI agents that can communicate with each other, make decisions collaboratively, and execute complex multi-step workflows. The goal is supply chains that are self-healing and self-optimizing.

D. Sustainability and green logistics

AI is becoming essential for achieving sustainability goals. Advanced algorithms optimize routes not just for speed but for minimal carbon emissions. They balance delivery speed against environmental impact, helping companies meet their climate commitments while maintaining service levels.

AI also enables circular economy models by optimizing reverse logistics for returns, repairs, and recycling. These systems identify the most efficient ways to recover value from used products and minimize waste.